A maintenance co-pilot app’s modules and features would enable insights and proactive decision-making

What specific modules and features might a maintenance co-pilot app include?

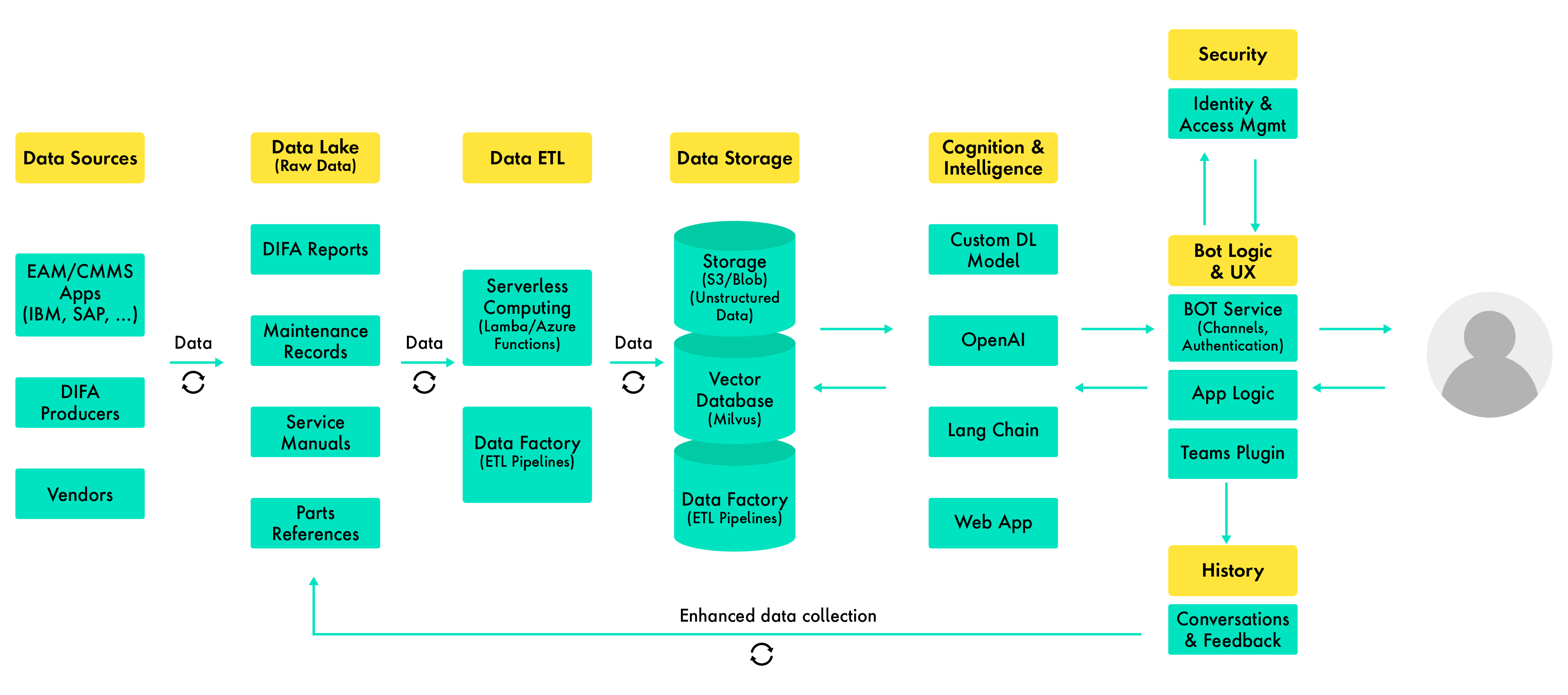

Data collection

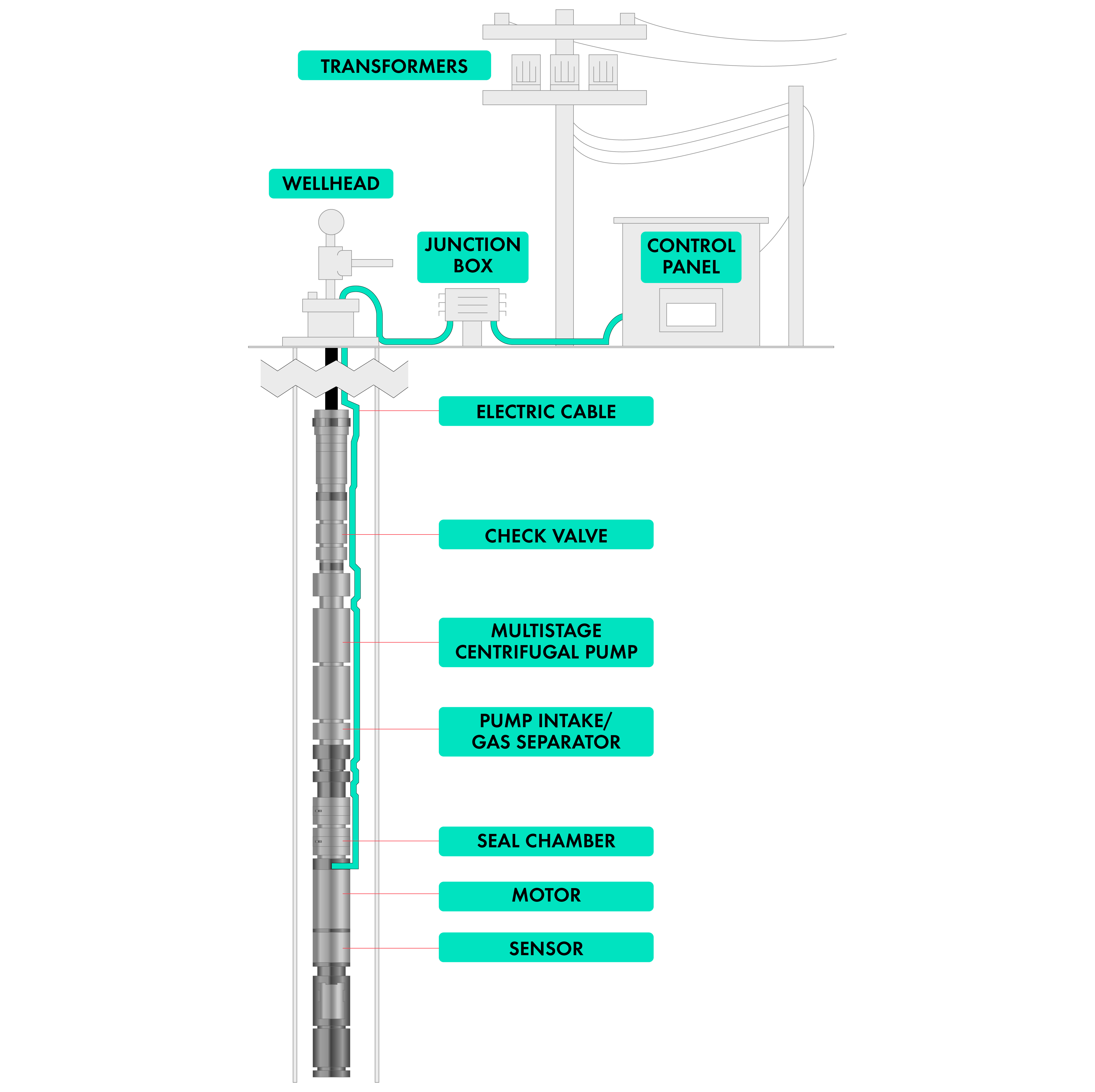

In addition to information about the ESP components from manufacturers’ manuals and guides, the app would tap into any of the maintenance system applications used at the customer facilities to continuously stream data into the system.

All this data is collected in a data lake, which is the entry point into the system. An Exact Transform Load (ETL) pipeline will analyze the input data and extract known structured information into a relational database, and unstructured data into a blob storage and vector database. This will make it easier for DL/ML models to process them.

Cognition and intelligence

This module is the brain behind the app, and it has a web application that hosts all models.

It receives queries from the technician via the bot interface and runs them through the custom-trained deep learning model which uses error codes, product descriptions and symptoms to classify the type of equipment malfunction. Using that outcome, it further processes the information through a custom large language model (LLM), trained and fine-tuned on a continuous basis.

Bot interface

This module is responsible for security and governance for the app. It also orchestrates the chat with the bot processing logic and chat interface with various frontend options. This enables technicians to select their preferred interface.

This also keeps a log of chat messages and responses and takes any feedback from the technician to retrain and enrich the model to close the loop.